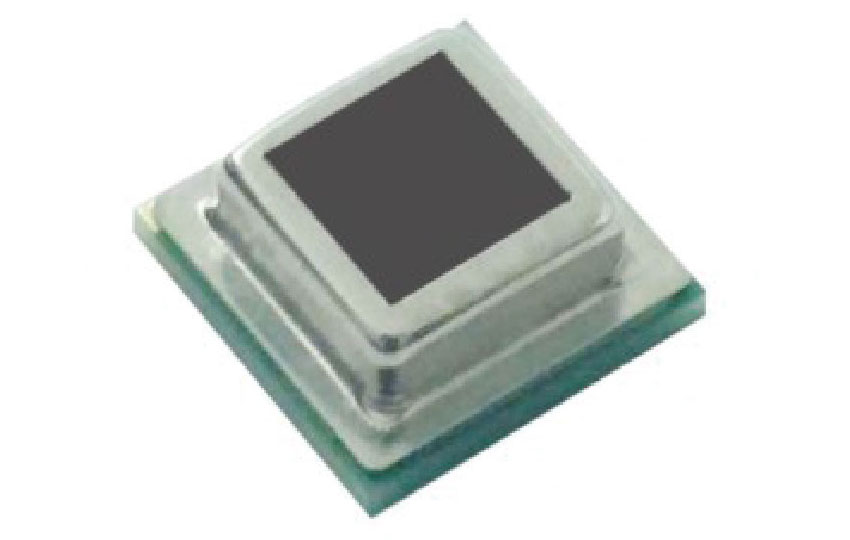

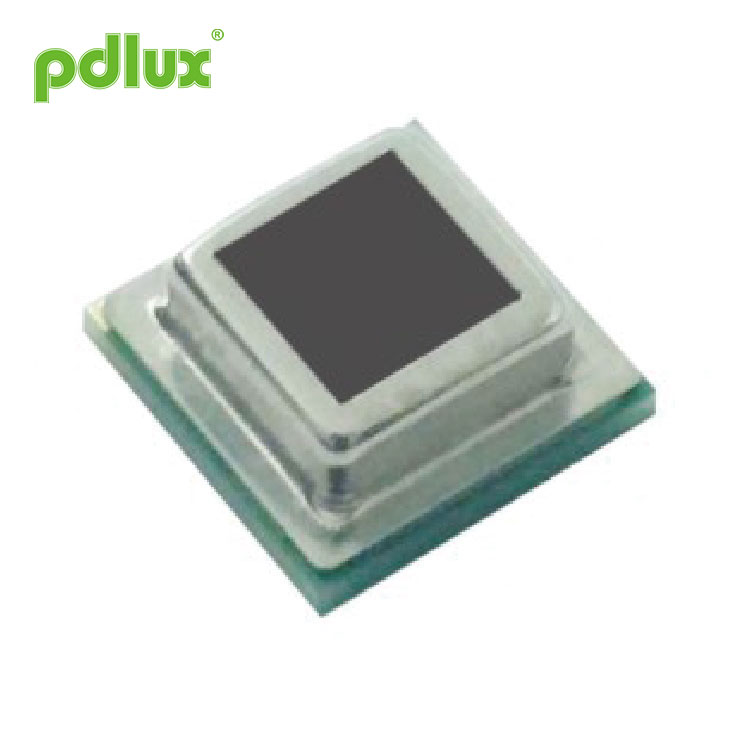

MINI SMD Four Element Analog Pyroelectric Infrared Sensor

Customers according to the type of tin paste used, reasonable adjustment of reflow welding process, such as high temperature tin paste, the recommended temperature is adjusted to about 260 degrees C, so that the tin paste fully melt, to ensure that the MINI SMD Four Element Analog Pyroelectric Infrared Sensor and PCB plate welding well. (*It is recommended that the customer complete the PCB board silk-screen tin paste, the corresponding sensor mounted position center to increase the process of dotting red glue, can improve the accuracy of the reflow welding welding position)

Model:PD-PIR-4021LA

Send Inquiry

Product Details

MINI SMD Four Element Analog Pyroelectric Infrared Sensor

|

Features of MINI SMD Four Element Analog Pyroelectric Infrared Sensor SMD reflow welding mounting process Analog signal processing Low voltage, micro-power consumption Ideal for ultra-thin product designs Stronger anti-jamming capabilities

Product and recommended pad size diagram

|

Application of MINI SMD Four Element Analog Pyroelectric Infrared Sensor Infrared motion detection Internet of Things Wearable device Smart home appliances: TVs, air conditioners, digital cameras, computers Automatic lighting switch: smart home, smart lamps Security, car anti-theft equipment LCD display Air purifier Network monitoring system, etc. Other |

Product packaging and identification

Schematic diagram of product tape packaging

1)The standard quantity of each product is 1000pcs.

2)Each product is knitted in a counterclockwise direction, and the feeding hole is on the left side of the user.

3)The label attached to each product clearly indicates the model, product quantity, production date, etc.

4)A green ROHS label is affixed to each product.

Basic parameters of sensor

Any working conditions that exceed the rated value in the following table may cause permanent damage or failure of the device.

Long-term operation close to the rated value of the device may affect the life and reliability of the sensor.

|

Parameter |

Symbol |

Min |

Max |

Unit |

Note |

|

Operating temperature |

TOT |

-30 |

70 |

℃ |

|

|

Voltage |

VDD |

3 |

10 |

V |

|

|

View angle |

θ |

X=110° |

Y=90° |

° |

Field of view istheoretical value |

|

Storage temperature |

TST |

-40 |

80 |

℃ |

|

|

Detection wavelength |

λ |

5 |

14 |

μm |

|

|

Infrared receiving electrodes |

|

2*1 |

|

2elements |

|

Equivalent circuit diagram

MINI SMD Four Element Analog Pyroelectric Infrared Sensor welding conditions and precautions

1.Please refer to the temperature curve shown in the figure below for the reflow soldering process. It is recommended to set the preheating zone, heating zone setting, highest temperature zone, and cooling zone.

2.If you use manual soldering to solder the PIR pads, you can use hot weathered tin from the back of the PIR mounting board to complete the soldering within 3 seconds. When manual welding is used, since the welding temperature is uncontrollable, the performance of the sensor may decrease due to over-temperature. Please try to avoid manual welding.

3.It is recommended that users try to use the recommended pad size in the specification when designing the sensor pad size.

4.Precautions for the welding process.

1)Do not touch the product pad with bare hands before welding the product, as this may lead to poor welding of the product.

2)If the amount of solder tin paste printing is not consistent or one side of the pad oxidation, may lead to welding on both sides of the pad tin speed is not consistent, resulting in the product welding process produced a "standstone" effect, and even the product after welding to escape the welding area.

3)If local pad oxidation will cause local tin failure, resulting in sensor performance is not working properly.

4)Customers according to the type of tin paste used, reasonable adjustment of reflow welding process, such as high temperature tin paste, the recommended temperature is adjusted to about 260 degrees C, so that the tin paste fully melt, to ensure that the product and PCB plate welding well. (*It is recommended that the customer complete the PCB board silk-screen tin paste, the corresponding sensor mounted position center to increase the process of dotting red glue, can improve the accuracy of the reflow welding welding position)

5)Do not repeatedly reflow welding or repeated heating repair, otherwise it will seriously affect the life and performance of the sensor;

6)Do not use corrosive chemicals before and after product welding to clean or wipe the optical filter on the sensor window cap (waterless ethanol is recommended for cleaning or wiping), as this may cause the sensor to fail.

7)After the sensor product completes the reflow welding, do not press the filter, otherwise it will cause the filter to sink, must be placed more than 2H for testing or use.

8)Please avoid touching the product filter and its welding terminals with metal sheets or bare hands.

9)The operator should wear an anti-static bracelet when taking the sensor.

10)Please strictly follow the specifications of the product welding feet for mounting welding, otherwise the sensor will not work.